Analysis of Embracing Digital Twin Technology

The central idea explored in the text revolves around ways in which companies can maximize product quality, efficiency, and security, especially in the wake of Industry 4.0. The text underscored the significance of effective maintenance practices and care of equipment.

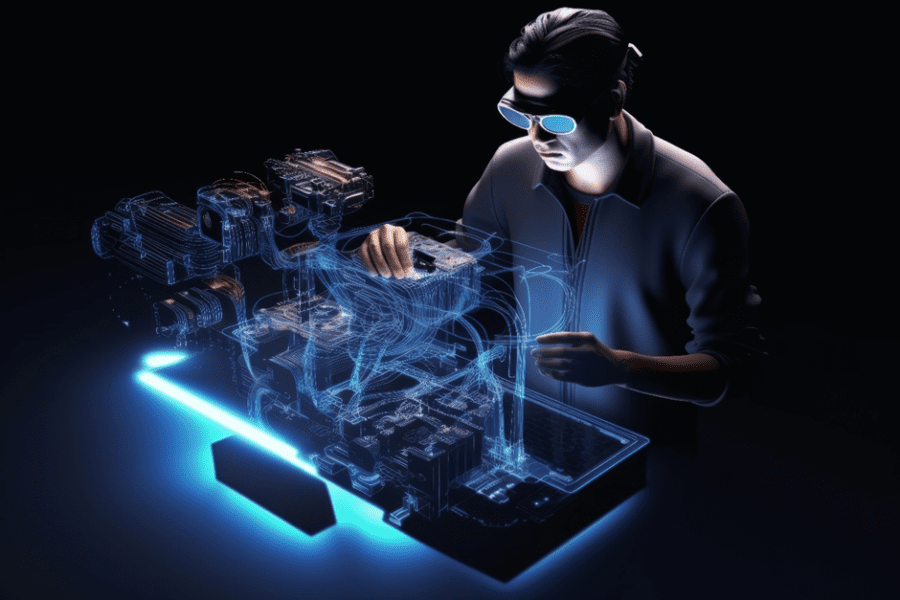

More importantly, the text highlighted the shift towards digital twin technology as a predictive and management tool used for complex assets in industrial setups. Replacing traditional time-consuming and expensive methods, this technology bodes large-scale changes for the manufacturing industry.

Long-Term Leadership Implications and Prospects

As more companies embrace digital twin technology within their manufacturing processes, several long-term implications can be inferred:

- Increase in Efficiency: Usage of digital twin technology to handle complex industrial assets could lead to increases in efficiency due to the reduction in time and cost spent on these tasks traditionally.

- Improvement in Quality and Security: The predictive capabilities brought about by digital twin technology promise an improvement in product quality and an enhancement in security protocols.

- Growth in Industry 4.0: As more businesses within the manufacturing industry adopt digital twin technology, we can expect rapid growth in Industrial 4.0 practices.

Potential Future Developments

Given the steady acceptance of digital twin technology, it’s reasonable to predict several future developments within the manufacturing industry:

- Advanced Automation: As digital twin technology continues to mature, we can anticipate a rise in advanced automation within manufacturing processes.

- Greater Predictive Capabilities: With technological advancement, further predictive and troubleshooting capabilities are likely to develop, potentially reducing downtime and losses.

- Increased Adoption Rate: As more businesses recognize the benefits of digital twin technology, we can expect a rise in its adoption across the manufacturing sector.

Actionable Insights

To stay competitive and make the most of the opportunities brought about by digital twin technology, businesses in the manufacturing sector should consider the following actions:

- Invest in the Right Tools: Companies should seek out reliable, advanced digital twin technology tools and invest in them wisely to achieve an edge over the competition.

- Upskill the Workforce: To leverage this technology fully, companies need a workforce that understands and can implement it effectively. Invest in ongoing training and development programs to ensure employees can keep up with evolving tech scenarios.

- Pursue Continuous Improvement: In an industry that is set to be dominated by digital twin technology, companies should continually innovate and improve their operations, workflows, and processes to stay ahead.